About North Thai

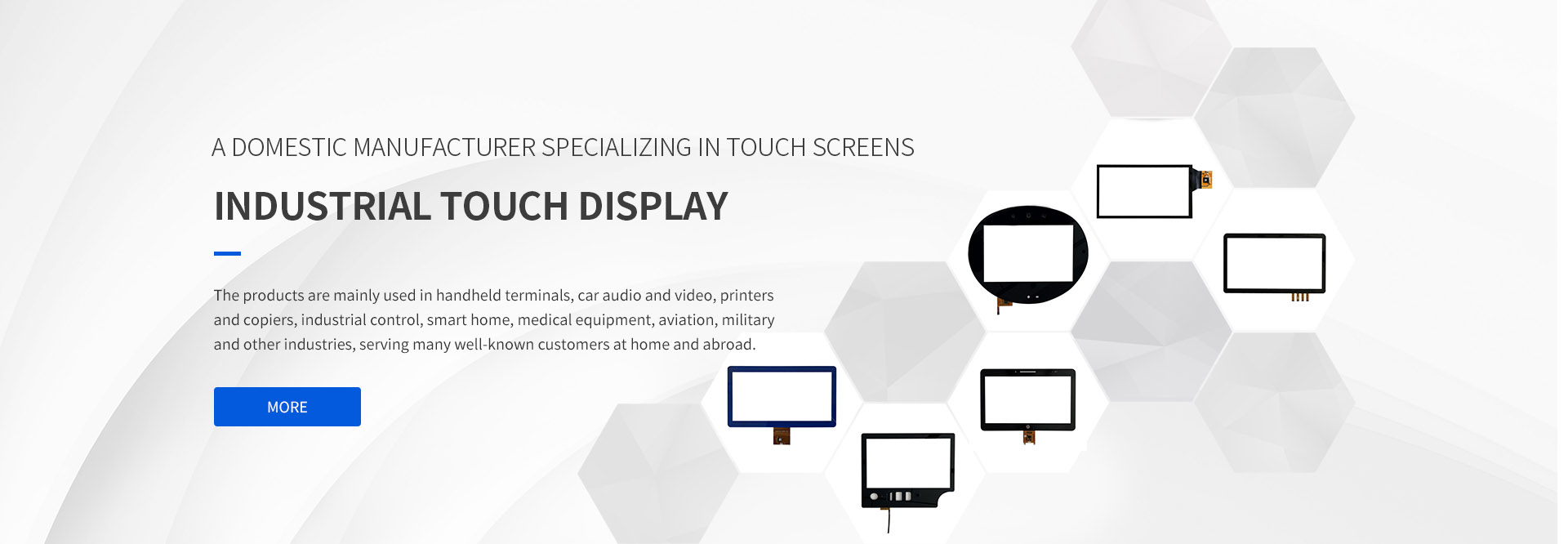

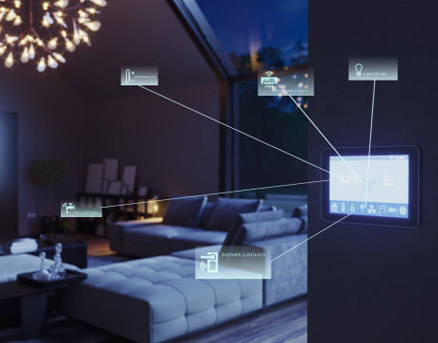

Shenzhen Beitai Display Technology Co., Ltd. was established in 2001, is engaged in industrial control touch display industry (industrial control, vehicle, medical, military high-end products) leading enterprises, is Shenzhen Longhua District top 100 enterprises, is Shenzhen specialized new small and medium-sized enterprises, is a research and development, design, production, sales in one of the "national high-tech enterprises"; The products are mainly used in handheld terminals, car audio and video, printers and copiers, industrial control, smart home, medical equipment, aviation, military and other industries, serving many well-known customers at home and abroad.

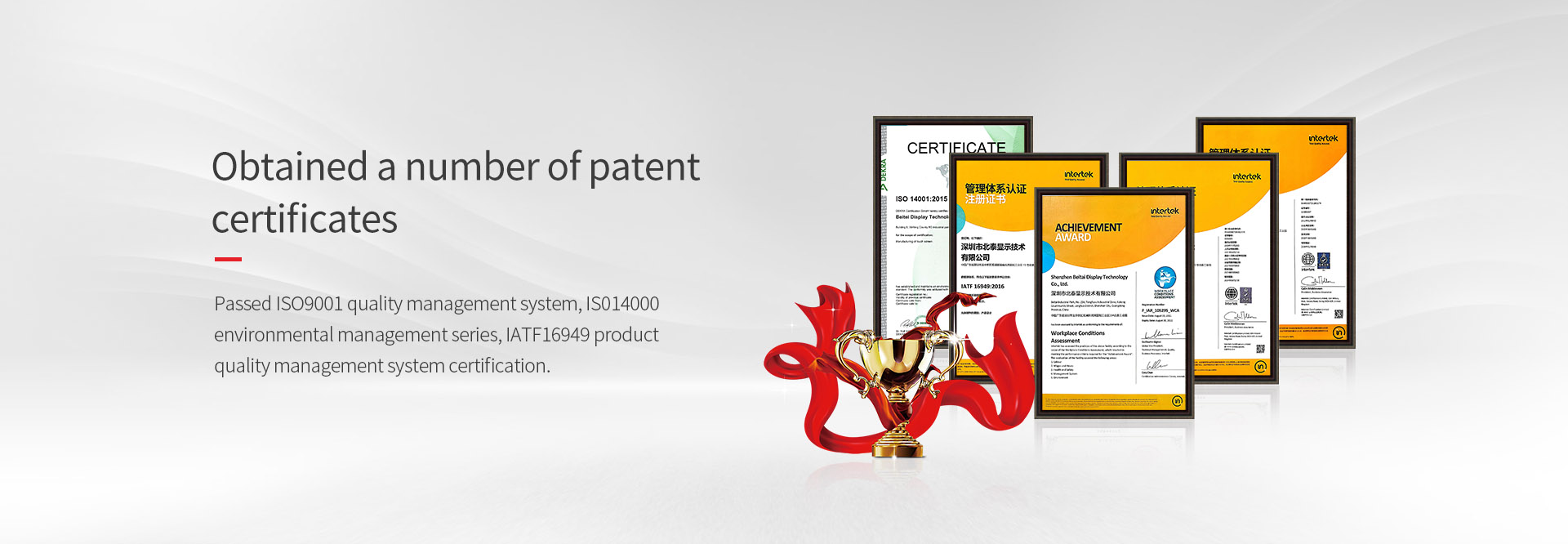

The Shenzhen company is located in the Beitai Industrial Park, Kukeng Tongrich Industrial Zone, Guanlan Street, Longhua New District, Shenzhen, covering an area of nearly 8,000 square meters, of which there are more than 3,000 square meters of super-clean workshops at million/million level. Passed ISO9001 quality management system, IS014000 environmental management series, IATF16949 product quality management system certification.

Beitai Display established a wholly-owned subsidiary Beitai Display Technology (Ganzhou) Co., Ltd. in 2021, located in 5G Industrial Park, Xinfeng County, Ganzhou City, Jiangxi Province, with a construction area of 23,000 square meters and 17,000 square meters of 10,000-level purification workshop (including 1,500m square meters of 100-level purification workshop), which has been put into operation. The second phase is 97.5 mu of land provided by the government to plan the construction of Beitai Industrial Park.

More01

More01